Special Design for Fluid Level Gauge - Liquid Level Indicator Ykjd Liquid Level Switch Series – Xinyuan

Special Design for Fluid Level Gauge - Liquid Level Indicator Ykjd Liquid Level Switch Series – Xinyuan Detail:

This level switch is a new type fluid level indicator. It can be used for auto controlling or alarming of fluid level in a tank or electric motor. Du ring operation, the float will rise orf- alldown with to the level of fluid in a tank. As the float rises or falls down to the level point preset for alarming or stopping the motor, the level switch will act, the normally open close.

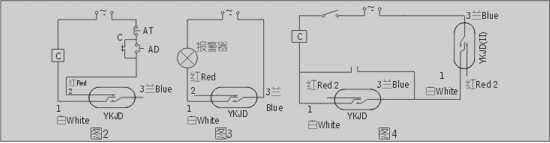

1. The figure 2 shows the application on oil tank. When the liquid level is lower than thep- osition required, the liquid level control relay YKJD acts; land 2are cut off, C coil of the inter mediate relay’s power supply is cut off, then the motor of oil pump stops working.

2. The figure 3 is used as liquid level control alarm device on the oil tank for hydraulic station. When the liquid level is lower than the position required, the liquid level control r- elay acts; lan(l3 are put through, then the alarm works.

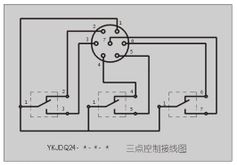

3.The figure 4 is applied on water accumulator or some auto, control oil tanks to realize a- uto. Water or oil supplies. The figure 5 and 6 are installation diagrams with the following principle: When the liquid level is lower than al, the liquid level control relayYKJD(I) acts(at this time, YKJD(II) is underwork condition, that means 1 and 3 are put through), 1 and 3 are put through, the current passes the C coil of intermediate relay (normally o- pen contact of C is closed) to make water or oil supply motor work; When the liquid level exceeds al, the relay YKJD(I) acts; 1 and 3 are cut off, the current passes though the normally open contact C (at this time, it is still underdosed state) to make water or oil supply motor continuously work; When the liquid level exceeds a2, the relay YKJD(II)a- cts; land 3 are cut off, water or oil supply motor stops working, then it descends with the liquid level, YKJD(II) acts; 1 and 3are put through, butl and 3 of YKJD (I)are still u- nderthe cut-off state, so liquid supply motor does not work yet, the liquid supply motor restarts until the liquid level descends belowal.

Note: when 220V voltage is used, there is only one pair of normally open contacts and impermanent closed contacts.

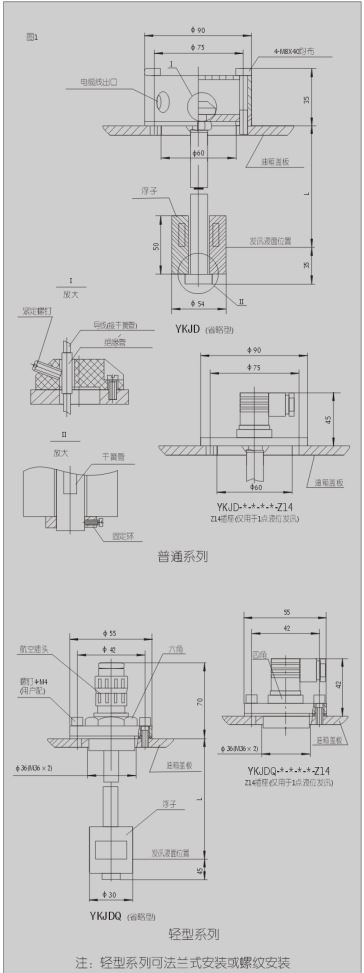

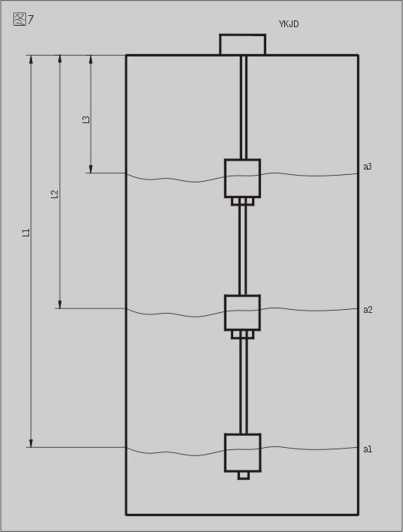

Use multiple single point level elevators to raise the level required

Note: The length desired refers to the figure 7,B is the cover plate top of oil tank, al, a2, a3 are liquid level si goal trans-mittin g positions, the user can select the length from b to al, a2, a3 according to the use condition.

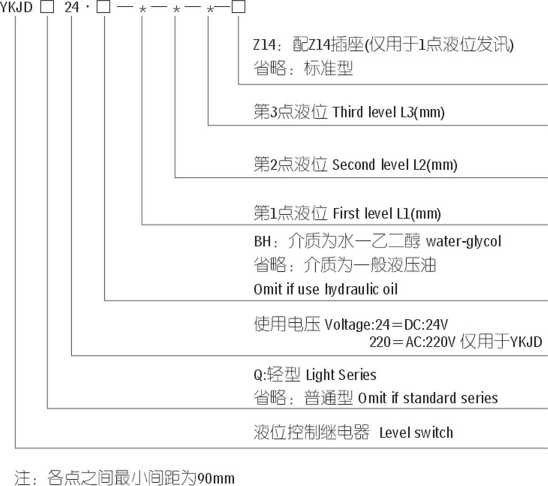

Example: (l)use one-point liquid level control relay to control the liquid level: When the distance from the cover plate b of oil tank to the liquid level signal-transmitting desired position is 800mm, the order model is YKJD24-800.

(2)use multi-point liquid level control relay to control the liquid level: When the distance from the cover plate b of oil tank to the first point a of desired liquid level is 1000mm, to the second point a is 500mm and to the third point a is 350mm, the order model is YKJK24-1000-500-350. If more control points are necessary, the model can be on the analogy of this.

1. Temperature range(°C): -20 〜+100

2. Time of motion(ms): 1.7

3. Contact resistance(Q): 0.1

4. Contact capacity:DC24(V) x 0.2(A)

5. AC220(V) x 0.02(A)

6. Life:(Time)10

Example: when the graph user wants to adjust the position of the transmitting point of L3 or L2 (the maximum ‘distance’ between each point is 90mm)

(1) Loosen the fixing ring below the float to be adjusted, adjust the float to the position to send information, and lock the fixing ring.

(2) Open the junction box, loosen the setting screw of the dry reed tube corresponding to the float just adjusted, move the dry reed tube, measure with a multimeter, and so on. After the signal is reliable, lock the setting screw to cover the junction box.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for Special Design for Fluid Level Gauge - Liquid Level Indicator Ykjd Liquid Level Switch Series – Xinyuan , The product will supply to all over the world, such as: Nepal, Spain, New Zealand, We warmly welcome your patronage and will serve our clients both at home and abroad with products of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.